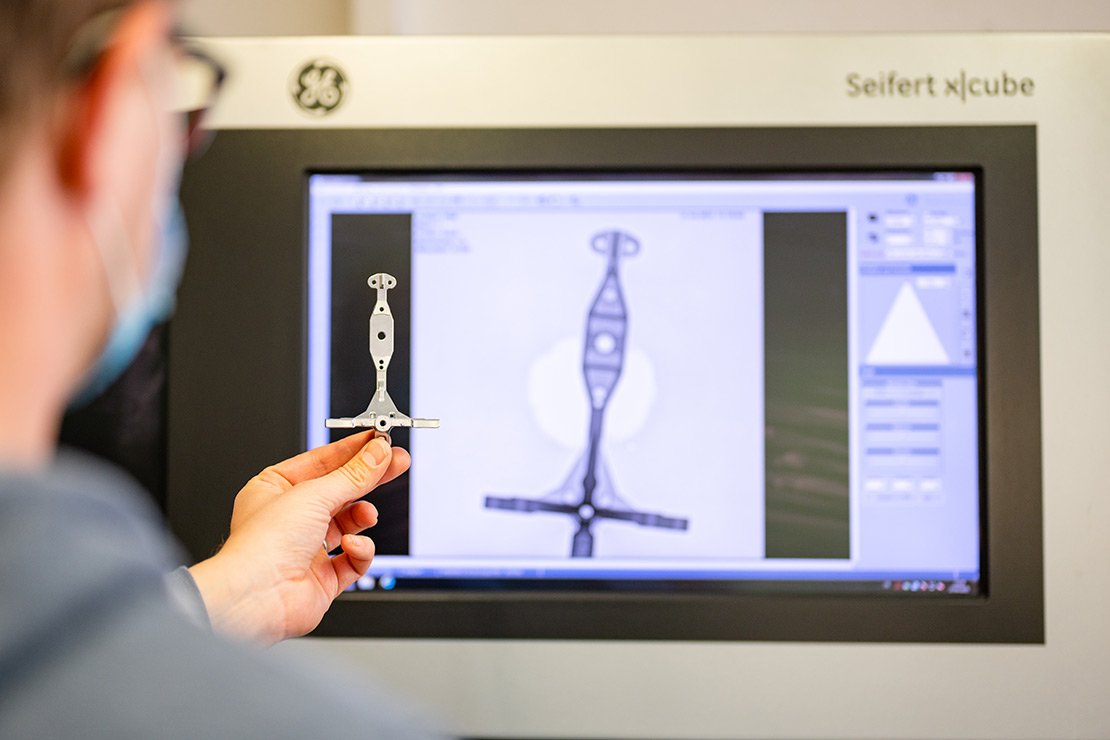

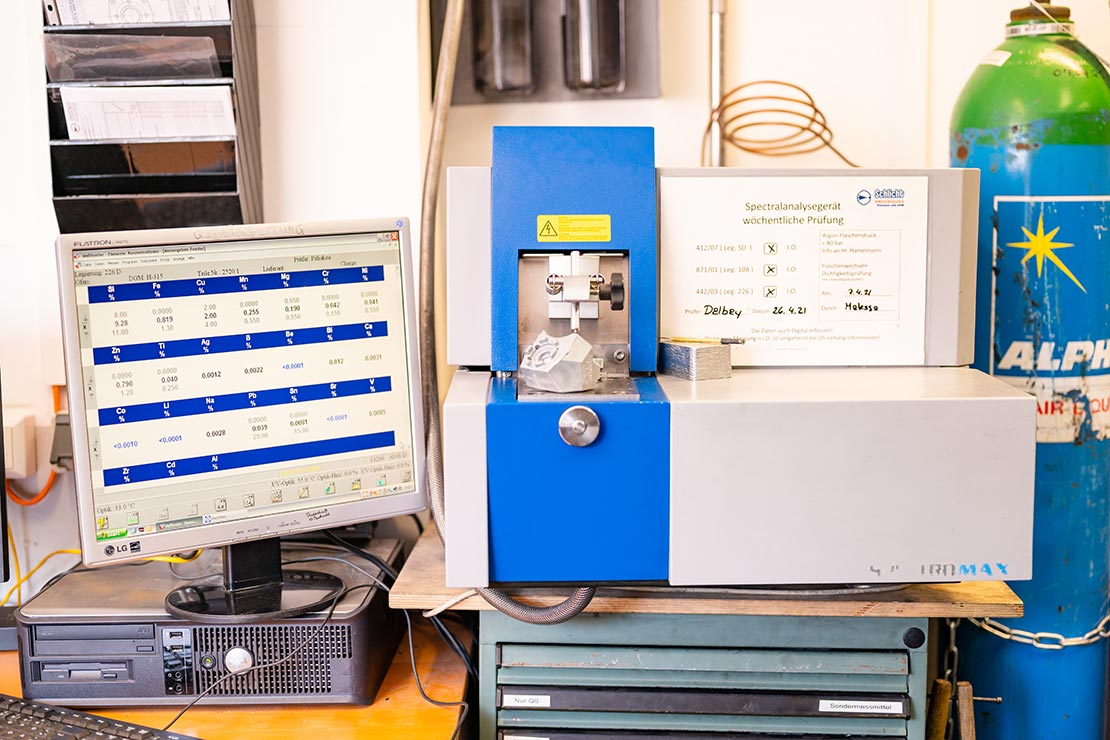

At Schlicht Druckguss you can be sure that you will only receive products "Made in Germany", because we do not compromise on quality. We have therefore installed seamless quality control along the entire production and supply chain. Safe and precise checks are carried out from the material inspection at incoming goods through all production and processing steps to the final inspection of the finished castings. State-of-the-art technologies such as spectral analysis or X-ray are used for this purpose. Our quality officers ensure that the highest standards are always maintained. This guarantees high availability and reliable reproducibility of the castings.

Highest quality standards

Already in the first consultation with you, the quality features and standards are clearly defined. Production-accompanying controls, an extremely high quality awareness of all employees as well as final inspections guarantee a consistently high quality standard. So there’s no need to fear nasty surprises. Our quality management is certified according to DIN EN ISO 9001:2008 and has been audited several times according to the automotive standards VDA 6.1. and IATF 16949.